Polyester, a term that has become synonymous with the textile industry, is a versatile fabric that has revolutionized the way we dress and utilize textiles in various applications. From the clothes we wear to the curtains that adorn our homes, polyester has made its mark.

Synthetic fiber is derived primarily from polyester material, with the majority being thermoplastic. Recognized by its abbreviation, PES, it stands as a testament to human ingenuity in the realm of textiles.

Artificial fiber that serves as a raw material in the textile industry. Its popularity as one of the world’s most sought-after textile raw materials is undeniable. The term “polyester” typically refers to fabric crafted from polyester fibers.

These fibers are frequently blended with cotton to produce garments that combine the best of both worlds.

- Popularity: Widespread use in textiles is evident in the diverse range of knitted and woven fabrics it contributes to. From taffeta and single jersey to rib and satin, polyester yarn is versatile, either used independently or mixed with other fibers.

- Chemical Composition: At its core, polyester is a polymer. It primarily consists of compounds within the ester functional group, making it a member of the condensation polymer family. This category includes renowned polymers like polyethylene terephthalate and polycarbonate.

The Global Impact of Polyester

The global textile industry has embraced polyester fibers, often blending them with natural fibers like cotton, wool, silk, and linen. Renowned by trade names such as Terylene (England), Dacron (USA), and Diolen (Germany), these synthetic fibers dominate the market.

- Versatility: Polyester’s adaptability is evident in its resemblance to natural fibers. Among artificial fibers, it bears the closest resemblance to cotton, meeting the increasing demand for cotton-like properties.

- Chemical Classification: Based on its chemical structure, polyester is categorized into three groups:

- PET (polyethylene terephthalate) fibers

- PCDT (poly-1.4 cyclohexyl-dimethylene-terephthalate) fibers

- Modified polyester fibers

How is It Made?

The creation of fabric is a testament to human innovation. The process involves intricate chemical reactions and precise manufacturing techniques.

The Production Process

Polyester fibers are derived through two primary methods. The first involves ethylene glycol and dimethyl terephthalate as starting materials, while the second employs ethylene glycol and terephthalic acid.

- Polymerization: The raw material, once polymerized, is cooled within the polymerization vessel. It is then transformed into small pieces, which are subsequently melted at a temperature of 260°C. This molten material is spun into filaments, which undergo stretching to enhance their strength.

- Applications: The primary polyester fiber, polyethylene terephthalate (PET), originates from the petroleum industry. Another variant, poly tetramethylene terephthalate (PTMT), caters to niche applications. Depending on the desired end product, PET yarn can manifest as filament or staple fiber, with varying lengths and finesse.

PET vs. PTMT

The distinction between PET and PTMT is crucial in the textile industry. PTMT, with its lower melting temperature, offers easier dyeing than PET. It finds applications in stretch jeans and clothing, especially when combined with PET.

- Properties: Standard boasts resistance to elongation, granting it anti-wrinkle properties and dimensional stability. However, PTMT excels in applications like pantyhose and tights, where PET falls short.

- Applications: Versatility is evident in its use in sewing threads, protective clothing, sails, and even car roof coverings. Innovations like air jet and false twist texturing techniques have further expanded their applications.

Properties of Polyester Fibers

Understanding the properties of polyester fibers is essential to appreciate their widespread use in the textile industry.

Physical Properties

Fibers, when observed microscopically, resemble smooth rods. Their round cross-section and general white coloration make them distinct.

- Fineness & Length: Polyester fibers can manifest in various lengths, either as filaments or staples, depending on their intended use.

- Strength & Absorption: With strengths ranging between 4-7 gr/denier for filaments, polyester fibers are robust. Their low moisture absorption (0.2-0.8% under standard conditions) ensures comfort in warm climates.

Chemical Properties

Polyester fibers exhibit resistance to a range of chemicals, including acids, solvents, and bleaches. Their resilience against environmental factors like sunlight surpasses many synthetic fibers.

- Heat & Combustion: With a melting point of 250°C, polyester products require careful ironing at low temperatures. When exposed to flame, polyester fibers retract and melt, leaving a distinct chemical odor.

The Evolution

The journey of polyester from its inception to its current status in the textile industry is nothing short of remarkable. As with many innovations, polyester has evolved over the years, adapting to the changing needs of consumers and industries.

Historical Perspective

The roots can be traced back to the early 20th century. However, it wasn’t until the mid-century that it began to gain traction, thanks to advancements in chemical engineering and manufacturing processes.

- Early Adoption: Initially, it was seen as a cheaper alternative to natural fibers. Its durability and ease of care made it an attractive option for everyday wear.

- Modern Usage: Today, applications have expanded beyond just clothing. From industrial uses to home furnishings, its versatility is evident.

Innovations in Polyester Production

Over the years, the methods of producing polyester have been refined, leading to better-quality fibers with enhanced properties.

- Sustainability: With growing environmental concerns, there has been a push towards producing polyester from recycled materials. This not only reduces waste but also decreases the carbon footprint associated with its production.

- Blending Techniques: Modern polyester is often blended with other fibers to achieve specific characteristics, such as moisture-wicking or UV protection.

The Environmental Impact

Production and Consumption

The production, especially when derived from petroleum, has environmental consequences. The extraction and refining processes are energy-intensive and contribute to greenhouse gas emissions.

- Water Usage: Production, especially dyeing, and finishing, can consume significant amounts of water. However, advancements in technology are aiming to reduce this consumption.

- Waste Management: The non-biodegradable nature of polyester means that it can persist in landfills for years. Efforts are being made to recycle polyester garments to mitigate this issue.

Sustainable Alternatives

The textile industry is increasingly looking towards sustainable alternatives to traditional polyester.

- Recycled: Derived from post-consumer plastic bottles, recycled polyester offers a more environmentally friendly alternative without compromising on quality.

- Bio-Based: Produced from renewable resources like corn or sugarcane, bio-based polyester is another sustainable option gaining traction.

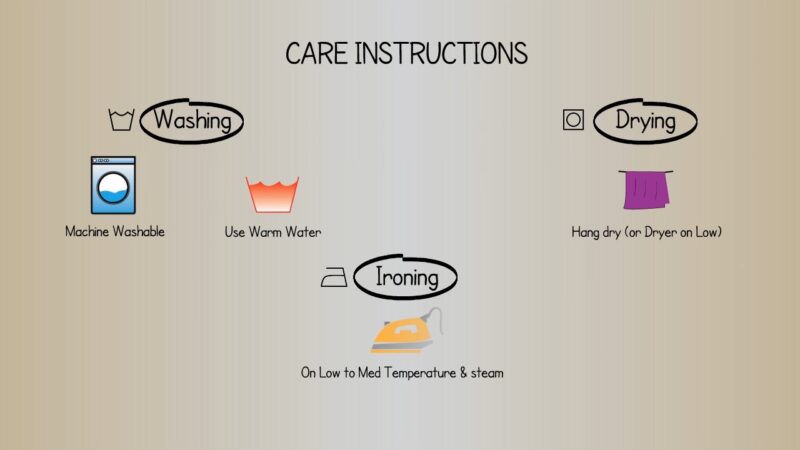

Caring for Garments

Washing and Drying

Garments typically require less frequent washing compared to natural fibers. When washing is necessary:

- Temperature: Use cold water to prevent shrinkage and reduce energy consumption.

- Detergents: Opt for eco-friendly detergents that are free from harsh chemicals.

Storage and Disposal

Proper storage can extend the life of garments, reducing the need for frequent replacements.

- Avoid Overcrowding: Ensure garments have enough space to breathe, preventing mold and mildew.

- Recycling: Instead of discarding old polyester garments, consider recycling them. Many brands and organizations now offer recycling programs for synthetic textiles.

FAQ

1. What is the difference between polyester and microfiber?

Microfiber is a type of polyester made from ultra-fine synthetic yarns. It’s softer and finer than standard polyester, making it ideal for products like cleaning cloths and bed linens due to its ability to trap dust and moisture.

2. Is polyester hypoallergenic?

Generally, polyester is considered hypoallergenic and is less likely to cause allergic reactions compared to natural fibers. However, some people might be sensitive to certain dyes or finishes used on polyester products.

3. Can polyester be dyed at home?

Yes, polyester can be dyed at home using disperse dyes, which are specifically designed for synthetic fibers. However, the process might be more complex than dyeing natural fibers.

4. Why does polyester sometimes have a static cling?

Polyester’s low moisture absorption makes it prone to static electricity. This can cause the fabric to cling to the body. Using fabric softeners or dryer sheets can help reduce this effect.

5. Is polyester fabric breathable?

Polyester is less breathable than natural fibers like cotton. However, many modern polyester fabrics are designed with breathability in mind, making them suitable for sportswear and other active applications.

6. How does polyester impact the environment compared to cotton?

While polyester production is energy-intensive and relies on non-renewable resources, it often requires less water and land compared to cotton cultivation. However, polyester is non-biodegradable, which poses challenges in waste management.

7. Are there eco-friendly alternatives to traditional polyester?

Yes, recycled polyester, derived from post-consumer plastic bottles, and bio-based polyester, made from renewable resources, are sustainable alternatives gaining popularity in the textile industry.

Final Words

Polyester, a fabric that has seamlessly woven itself into the fabric of our daily lives, stands as a testament to human innovation. Its versatility, durability, and adaptability have made it a staple in the textile industry.

As we move forward, it’s essential to approach its use with a sense of responsibility, ensuring that our choices are sustainable and environmentally conscious. By doing so, we not only preserve the legacy of this remarkable material but also ensure a brighter future for our planet.